Effective Ways to Determine How Long Does It Take for Concrete to Dry in 2025

How Long Does Concrete Take to Dry?

Understanding Concrete Drying Time

When working with concrete, **understanding how long does concrete take to dry** is crucial for project planning and execution. Concrete drying time varies based on a multitude of factors including mix design, environmental conditions, and the specific application of the concrete. On average, it can take anywhere from a few hours to several days for concrete to set and dry sufficiently for pedestrian traffic, and much longer for heavy loads. **Concrete setting time** generally ranges from 24 to 48 hours for light traffic, whereas full strength is often achieved after 28 days. Knowing these timelines helps ensure that the structure can withstand the stresses of usage without compromising integrity.

Factors Affecting Concrete Drying

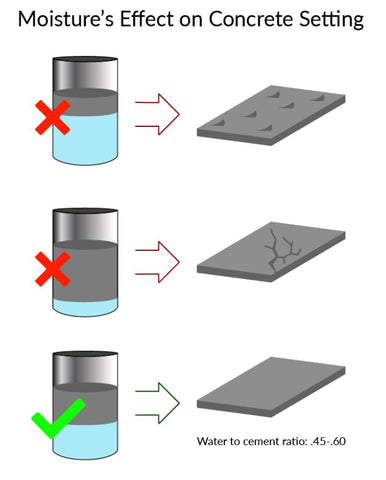

Several key factors influence the **time for concrete to set** and dry. The **moisture in concrete curing**, ambient temperature, and humidity levels all play critical roles. High humidity may prolong drying times, while lower humidity can accelerate the process. Additionally, the type of concrete—whether quick-setting mixes or standard concrete—can also drastically affect the **drying time for different types of concrete**. Other significant considerations include wind speed, as a gentle breeze can help evaporate moisture faster, and the thickness of the concrete slab. Understanding these factors will help any contractor plan their projects more effectively.

Ideal Conditions for Concrete Drying

To achieve optimal **concrete curing temperature**, it is important to work under ideal environmental conditions. The best drying conditions usually occur when temperatures are between 50°F and 85°F (10°C to 30°C). At these temperatures, the concrete can **dry effectively** without rapid moisture loss that can lead to cracking. During dry, warm days, it may also be beneficial to cover the concrete with plastic sheeting or curing blankets to retain moisture while still allowing some air circulation — reducing the risk of cracking or poor surface finish.

Methods to Speed Up Concrete Drying

For many contractors, the goal is to achieve quick drying without compromising the concrete’s quality. Implementing some of the **best practices for concrete drying** can dramatically reduce the time it takes for concrete to get traffic-ready. Options like using **chemical curing agents for concrete** or adding special **additives that speed up concrete drying** can be explored to hasten the process, as well as **drying concrete with heaters** in colder climates. These methods will ensure a shorter wait time before the concrete can be utilized, which can be especially critical in commercial projects.

Common Tools for Monitoring Concrete Drying

Monitoring **concrete moisture content** during drying is vital for ensuring it cures properly. Tools such as moisture meters can accurately detect moisture levels in both freshly poured and set concrete. These devices can assist workers by indicating when concrete is ready for **the application of sealants** or other coverings, as well as providing real-time feedback on curing progress. Correctly understanding and measuring moisture not only helps determine **how long does concrete take to dry** but also prevents issues related to excess moisture, such as mold growth or surface imperfections.

Understanding Concrete Hydration

One of the underlying processes to consider while estimating **drying concrete in cold weather** is understanding how concrete hydrates. Concrete does not simply “dry”; it undergoes a chemical reaction known as hydration. This process is affected by several factors, including the amount of water used in the mix, the age of the concrete, and the temperature. Notably, the **effect of humidity on concrete drying** cannot be ignored, as higher humidity can slow down the application of water-soluble sealants. Therefore, educating oneself on the distinction between curing and drying is essential for achieving the project’s expected outcomes.

How to Tell if Concrete is Dry

Many wonder, “**how to tell if concrete is dry**?” There are several indicators, both visual and tactile. A common method involves performing a simple thumb test or using a moisture meter. Furthermore, concrete tends to lighten in color as it dries. It’s also crucial to remember that drying is different from curing; even when the surface appears dry, the inner layers may still retain moisture. Therefore, it’s advisable for project managers to routinely check internal moisture levels to confirm readiness. After approximately 28 days, concrete should have reached 95% of its designated strength but specific appraisals might dictate an earlier review period to assess if **how long before concrete can bear weight** aligns with traffic needs.

Visual Indicators of Concrete Dryness

Visual indicators serve as quick assessments to ascertain concrete’s readiness. Uneven surface coloring, cracks, or a tacky texture indicate that the concrete is still not adequately dried. By observing these signs, contractors can make better decisions regarding whether additional solutions or protective methods are needed to assist in the drying process. Moreover, providing a humidity level reference guide will aid workers in determining specifics such as the **drying concrete faster with fans** technique or which **moisture retention methods for concrete** may be most effective.

Assessing Concrete Drying Success

To assess the success of the concrete drying process, project managers should enforce a spread of quality check methodologies. Incorporating tools for **measuring concrete moisture** or employing techniques like the water puddle test can offer further clarity on concrete integrity after curing. Understandably, different projects will necessitate diverse strategies, which underscores the importance of acquainted quality measures as part of regular maintenance strategies in concrete care. This knowledge becomes crucial for residential and commercial projects alike.

Conclusion

Determining **how long does concrete take to dry** accurately requires an understanding of numerous variables. By properly addressing **factors affecting concrete drying**, utilizing strategic methods to accelerate the process, and monitoring drying methods, contractors can effectively plan their projects and ensure safety. Prioritizing these practices will lead to maximized performance in concrete applications, achieving lasting durability while minimizing potential setbacks.

Key Takeaways

- Concrete takes anywhere from a few hours to several days to dry depending on multiple factors.

- Optimal conditions for drying include moderate temperatures and low humidity.

- Methods like chemical agents and proper moisture monitoring can expedite concrete drying time.

- Physical and visual inspections are vital for assessing concrete dryness and readiness for traffic.

- Success in concrete projects comes from understanding hydration versus drying and implementing best practices.

FAQ

1. What is the typical drying time for concrete?

The typical drying time for most concrete mixes is about 24 to 48 hours for light use; however, it’s recommended to wait at least 28 days for full strength development.

2. How does weather impact the drying process?

**Weather conditions**, particularly humidity and temperatures, can significantly influence **concrete drying time**. High humidity levels slow down the process while warmer temperatures and lower humidity facilitate quicker drying.

3. Can I walk on concrete after 24 hours?

Generally, yes, you can walk on concrete after 24 hours, but ensure that it is completely dry and set according to the **traditional curing duration**, which is often a minimum of 48 hours for best results.

4. Are there specific methods to fast-track drying?

Yes, methods such as using **drying concrete with heaters** in cooler months or applying **curing compounds** can help speed up concrete drying and minimize downtime.

5. How do I know if the concrete is dry enough to apply sealants?

Using a moisture meter or conducting visual checks on uniformity and color can indicate **how to check concrete curing** readiness for sealant application.

6. What are some reasons for slow concrete drying?

Slow drying can occur due to high moisture content, adverse weather like high humidity, or inadequate ventilation. It is crucial to address these factors promptly to enhance drying efficiency.